Helping brands stand out with high-quality finishes and effects

We offer the following finishing technologies across our many facilities

Die Cutting & Blanking Capabilities

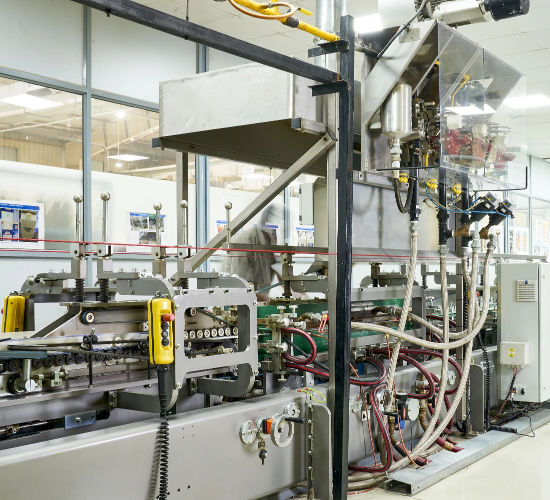

Folding & Gluing

From side pasting, crash lock to double pasting, our manufacturing facilities are equipped to offer a host of packaging solutions. Our folder gluers can also execute Accu-braille and hot melt operations efficiently.

Litho Lamination (Fluted Cartons)

Each of our plants has a corrugation section and is equipped with lamination machines to cater to pre-printing and post-printing lamination. The corrugation machines are used to make 3-ply cartons from corrugated sheets in the desired flute forms (B, E, F, G and N Flute).

Window Patching

Our manufacturing plants are equipped with single and double-feed window machines, for both U and V cut options. We also offer a value addition of pasting the inside liner with the help of the liner machine, which can perform the plain window operation.

Security features

- Micro Text

- Invisible Ink

- Hidden Text/ Logo

- Unique QR Codes

- Smart Connected Packaging

Tactile Coating

Tactile coating generates effects that directly alter a person’s sense of touch. With the objective of creating tactile effects (raised effect) Parksons has developed TaQto™, a special type of coating that

helps create the raised / tactile effects. Various textures can be generated to give a look and feel of

micro-embossing, with the added advantage that it does not deform the substrate. Also, the

coating’s glossy nature makes it premium, thus making it apt and popular for segments like Liquor,

Tobacco and Perfume.

Foil Stamping

Hot stamping or foil stamping is a printing method of relief printing, where foils are transferred to a surface at high temperatures. The foils used are high-end metallic films that are available in a wide variety of colours, and holographic effects. Foil stamping gives the finished product an eye-catching

metallic effect and better shelf appeal.